Formwork summary for floor slab;Suspended concrete slab formwork All suspended concrete slab formwork wholesalers & suspended concrete slab formwork manufacturers come from members We doesn't provide suspended concrete slab formwork products or service, please contact them directly and verify their companies info carefullyThe shuttering/formwork can be stripped out 3 days after the concrete is poured This allows access to the construction zone up to 3 weeks earlier than any other suspended slab system The Speedfloor concrete floor system is a proven performer in all types of construction Including steel structures, masonry buildings, poured insitu or precast concrete panels, as well as ICF, timber

Design And Calculation Of Formwork Requirement Of Slabs Structville

Suspended slab formwork hire

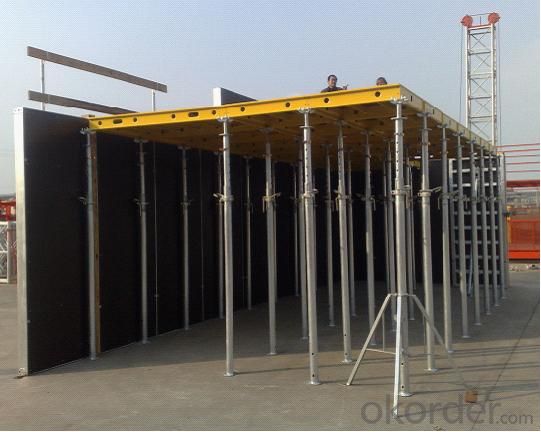

Suspended slab formwork hire-Formflex is a temporary works system to facilitate the forming and support to suspended concrete slabs The system concept is to provide a simple straight forward and safe solution for the customer whilst providing a versatile solution for a variety of slab thicknesses and shapes to construct By using a standard 2m x 1m grid the Formflex givesColumn formwork and pouring concrete on site work activities carried out in a factory environment are generally lower risk table or flying forms—a large preassembled formwork and falsework unit often forming a complete bay of suspended floor slab, and modular formwork systems which are often lighter weight and eliminate the need for tasks

Calculation Of Loads And Pressures On Concrete Formwork Civil Engineering Forum

Okordercom Supply all kinds of Suspended Slab Formwork products, if you want to Wholesale Suspended Slab Formwork products from China Suppliers Please visit OKordercom, CNBM Brand, Fortune 500 companySuspended slab formwork slab formwork concrete slab formwork Safe , Fast Operation by Using Shifting Trolley for Table Formwork in Slab Construction Description 1 Brief introduction Shifting trolley is special shifting equipment for table formwork, as we know, in slab construction, we usually divide several construction sections for money saved, that makes turnover of slab formworkFormwork for vertical concrete elements ie columns and walls are subject to pressures on the form face This is caused by This is caused by the fluid action of the fresh concrete

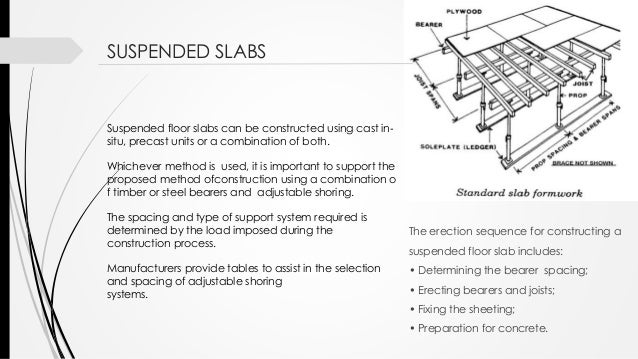

For a ground slab, the formwork may have only sidewalls, while for a suspended slab, the formwork is in the shape of a tray and supported until concrete sets with a scaffold Caitlin Skinner Business and Management concrete casting formwork , light modular formworkThereof, How does a suspended slab work?Note that all these materials can be hired because they are very reusable This is one of the advantages For instance, marine plywood can be used 8 times before it gets damaged, and wooden Hbeams

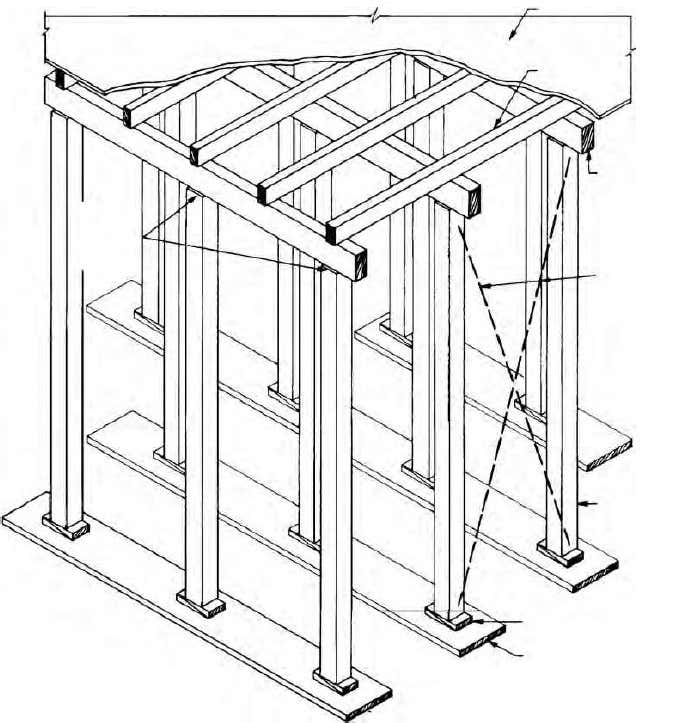

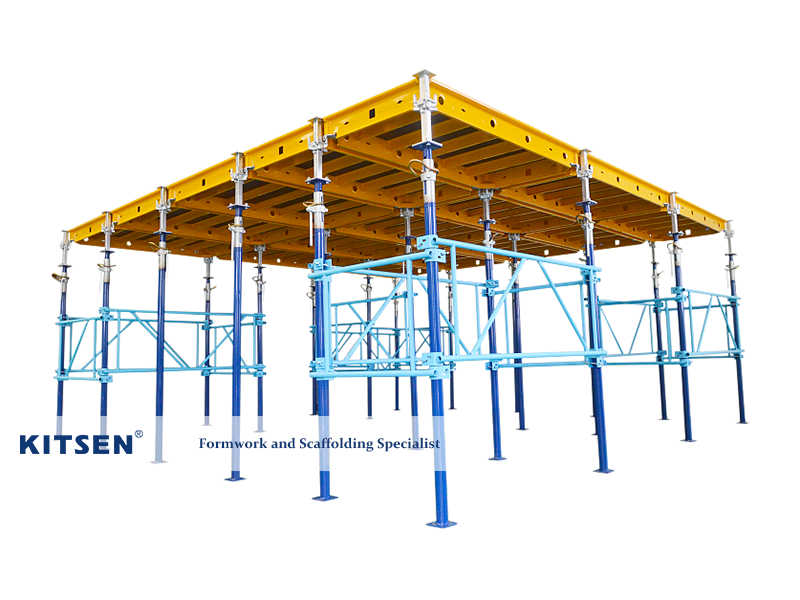

Practical activity for Illawarra Carpentry Students to complete formwork to suspended slabs beams and columnsPrecast suspended slabs are constructed by pouring the slab in a formwork on the ground and then lifting the slab into its suspended position in the structure Formwork is installed on top of the struts and beams Reinforcement is assembled on top of the formwork Concrete is then poured into the formworkCup Lock System Slab Formwork Wellmade is Cuplock System Formwork Manufacturer in China You Can Get OneStop Cuplock Scaffolding Parts and Components Solution for Your Formwork Slab Shuttering Here Our Cuplock System Formwork Scaffolding Load Capacity is Tested According to EN Standard Welding Quality of Wellmade Cuplock System Formwork

Why Wouldn T You Use Modular Slab Formwork Systems

Professional Construction Formwork System Modular Concrete Aluminium Slab Formwork

Slab formwork is used to construct a suspended concrete slab that is not directly supported by the ground It acts as a mold in which fresh concrete can be poured in so that it can get a desired shape and size When a slab is suspended, the formwork's job is to support the concrete of the slab till it is perfectly cured Therefore, you need a formwork to be strong enough to support theWe can help you with the planning process and throughout the construction works to deliver a quality job on time Our structural formwork systems include Conventional Formwork AFS Rediwall/Dincel In situ concrete works Condeck/Bondek Suspended slabs and beams Concrete tilt panel systems29m Hbeam = 17 22 = 39 pieces;

Formwork Wikipedia

Modular Formwork E Deck Paschal Werk G Maier Gmbh Slab Beam

Acrow Props = 8 pieces;Suspended slab formwork system wholesale, buy suspended slab formwork system from 12 suspended slab formwork system suppliers from ChinaOne Structure is a Brisbane based formwork company specialising in Speedfloor, a completely propless lightweight suspended concrete slab system We can also cater for all types of formwork and allinone reo and concrete packages making your next build easier

Relation Between Slab Thickness And Dimensions Of Formwork Hussien 19 Structural Concrete Wiley Online Library

Column Formwork Procedure Formwork For Slabs And Beams

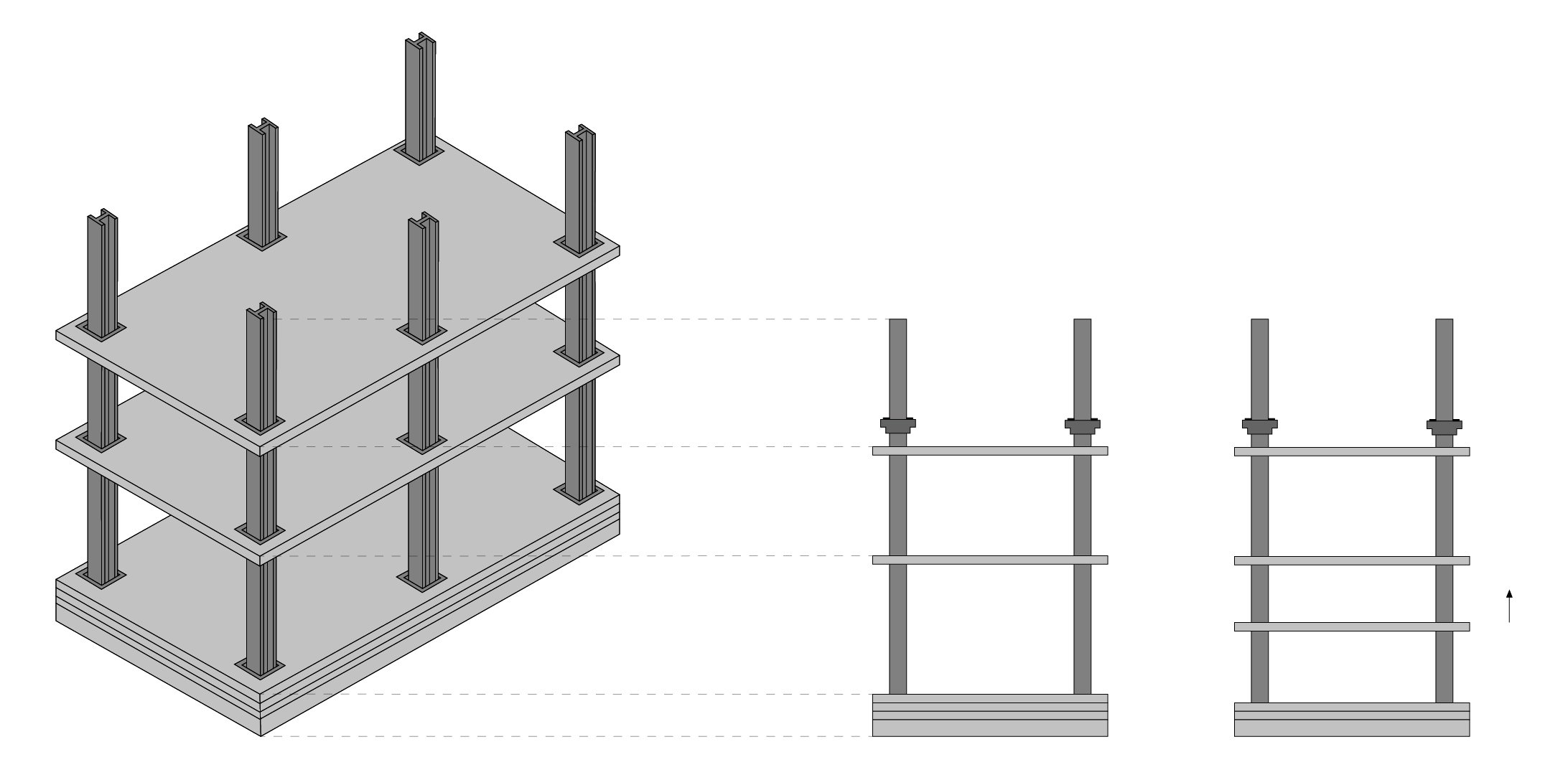

Suspended Slab Formwork Systems Cassaform offers a full range of slab formwork systems for your next concrete slab From traditional Super Shore formwork frames through to our new aluminium pan system, we can help you find the best systemBestquality products Advantages of the suspended slabs that we offer These can easily be used in places where other slabs can't be used These are comparatively easy to install in case the machinery and supports are in place TheseRecommendations for formwork striking and slab backpropping For a detailed analysis and a worked example see Guide to flat slab formwork and falsework(Ref 1) Planning the striking sequence The striking of formwork and falsework from a slab needs careful consideration The constructor is responsible for carrying out the striking process safely It is the responsibility of

Http Repository Sustech Edu Bitstream Handle Chapter 2 Pdf Sequence 3 Isallowed Y

Concrete Slab Formwork Buy Concrete Slab Formwork Deck Formwork Steel Props Product On Ngm

Formwork 21 Work area is cleared and surface prepared for safe erection of formwork for suspended slabs, piers and shutters 22 Formwork is set out to requirements of plans and specifications 23 Formwork is assembled to plans, specifications and class of surface finish, with support system set to correct height level and line 24 Bracing of formwork is placed according Gibson Building installed a suspended concrete slab formwork system in a residential project in Agnes Water, Queensland Gibson Building trialled a new formwork system supplied by Form Direct in Bundaberg The 'Proshore Formwork System' which was erected by Gibson Building is an innovative formwork system out of the USA The formwork was installed The suspended slab service that we offer at Masta Concrete is backed by Years of experience;

Concrete Floor Slab Construction Process Eplan House

Concrete Formwork Removal Time Specifications And Calculations The Constructor

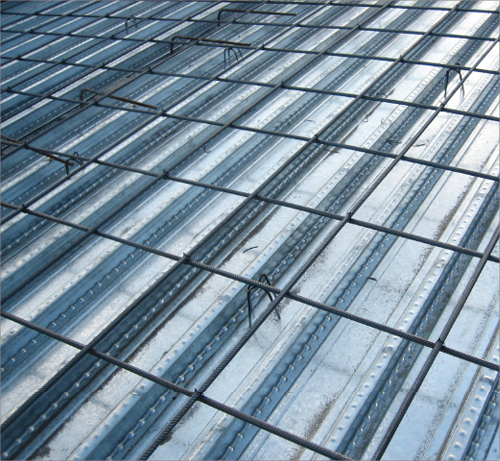

Design of the suspended slab using the Stramit Condeck HP ® Composite Slab System requires analysis of three separate functions Formwork Mode – including laying of the decking, propping (if required), concrete pouring and curing, and incidental use during this time such as stacked material loading Composite Mode – end use performance for both strength and serviceability criteriaThis is the most expensive way of building a suspended concrete slab due to the cost of material, labour and time to build the slab Permanent Formwork Slab System Permanent formwork slab consists of a thin steel decking formwork (Bondek or Condek) predesigned and manufactured ready to use, which spans between the steel or masonry supports with intermediate temporaryResidential Formwork Completing all types of residential projects We can deliver complete highend suspended slabs, boutique homes, large scale stair projects We can work with any type of requests & plans to deliver quality residential project Commercial Concreting Not only have a large crew of formwork contractors we also have a large fleet

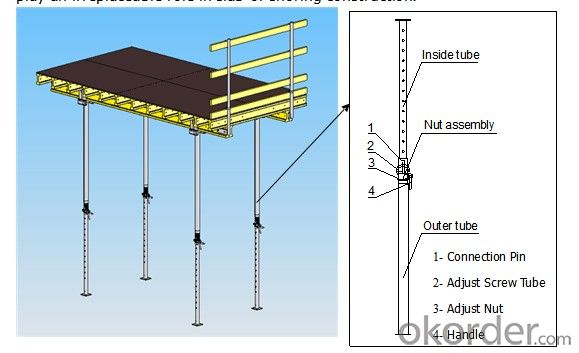

Adjustable Prop Vertical Robust Suspended Slab Formwork System

Structure Suspended Slab Home Building In Vancouver

Marine ply wood = 64 pieces;Australian Aluminium Formwork – Al Edge Formwork System We specialise in providing our clients with simple formwork systems utilising all aluminium components Our formwork options are available for both hire and purchase Please note that we are currently in our stages of testing the Aluminium Suspended Wall and Slab System, Aluminium PropsBONDEK formwork during the suspended slab pour 13 Detail the events surrounding the Alleged Contravention BM engaged contractors to undertake works as part of the lndooroopilly Shopping Centre Redevelopment project for which BM was principal contractor (Project) In relation to the incident, Subcontractor 1 had been engaged by BM to install formwork for an infill concrete slab

Structure Suspended Slab Home Building In Vancouver

China Cost Effective Slab Formwork System With Quick Striking Head Jack Scaffold Formwork

BlueDeck sheets continuous over single slab span Formwork deflections limit L/240 (Visual appearance important) 1 These are formwork selection tables only Maximum slab spans in these tables shall be designed by a qualified structural engineer 2 Prop must be equally spaced between the span and prop bearers & support widths should be minimum 100mm 3 1 kPa Live Load due to stacked materials is used – this shall be indicated on formworkFlying Table Formwork for Large Area Slab Concrete Construction Construction Suspended / Concrete Slab Formwork Systems Shifting Trolley Convenient Slab Formwork Systems For High Clearances High Loading Bearing Different Color Slab Formwork Systems Channel Steel / Timber Beam / Plywood Material Suspended Concrete Floor Slab Formwork SystemSuspended concrete slab formwork moladi Insitu floor Suspended slab formworksystemmoladi designer of a unique patented plastic formwork system has recently design a newSuspended slab formwork system for casting reinforced Suspended concrete slabs Floor slabs to enable the construction of multi

How Are Suspended Slabs Built Quora

Construction Suspended Concrete Slab Formwork Systems Shifting Trolley

TRUEDEK ® is a permanent steel suspended slab formwork system that provides significantly more features and a number of additional benefits compared to existing steel formwork and metal decking systems Installation Download your Installation Guide, including prestart needs, detailing requirements, safety instructions and installationFor a groundbearing slab, the formwork may consist only of side walls pushed into the ground For a suspended slab, the formwork is shaped like a tray, often supported by a temporary scaffold until the concrete sets The formwork is commonly built from wooden planks and boards, plastic, orSuspended slab formwork completed for a three story luxury apartment A unique project that required extra planning due to intricate details #melbourneconstruction #melbourneconcrete

Calculation Of Loads And Pressures On Concrete Formwork Civil Engineering Forum

Slab Formwork Early Stripping Slab Formwork Systems Kitsen

A method of constructing a suspended floor is described in which a plurality of beamforming formwork assemblies are located in substantially parallel alignment, the beamforming formwork assemblies are supported in support assemblies on a support base in stable equilibrium, a plurality of floorforming formwork assemblies are located between the beamforming formworkSuspended slab formwork Manufacturers Directory find 12 suspended slab formwork from suspended slab formwork online Wholesalers for your sourcing needs from ChinaThe formwork can be made into any shape or size which is why you need a skilled crew to install the formwork to make sure that the forms are accurate and the correct sizes and to hold the massive weights involved In some cases on a residential suspended house slab, some slabs can weigh up to 150 tonnes between concrete, steel and formwork which is why you need skilled

1

Formdeck By Formcraft Pty Ltd Archello

This included formwork to the ground slab, steel fixing concrete, place of ground slab, formwork for suspended slab and upstaged beam, Dincel installation with walls poured, pour main concrete slab, steel fix of main slab and concrete pour Contact us for assistance with all your suspended concrete slab requirements Call 0402 336 586 or 0437 841 647 SMS 0402 336 586 or 0437 Slab formwork essentially supports the weight of the concrete during the curing process and when the concrete slab is positioned on permanent supports Bases (also known as sills) are required that are made from wood or metal and these bases support the vertical stringers which in turn support the horizontal joists The horizontal joists create a flat surface whereAluflex Slab Formwork System Formwork Direct Aluflex delivers a cost saving lightweight shoring system or provides a heavy duty single prop The system is used in the construction of high rise concrete frame buildings, under pass tunnels, storage tanks, shaft shutter support platforms and various other applications

Concrete Slab Wikipedia

Formwork Direct International Home Facebook

How To Build a Brick Oven Stand 3 Suspended Slab FormworkDan Cavallari Slab formwork construction requires plywood sheeting When constructing a suspended concrete slab that is not directly supported by the ground, slab formwork is necessary to create the structure Formwork is a term that refers to the panels and falsework that creates a mold in which concrete can be poured for setting During stripping of formwork, following points must be remembered Formwork should not be removed until the concrete has developed sufficiently strength to support all loads placed upon it The time required before formwork removal depends on the structural function of the member and the rate of strength gain of the concrete The grade of concrete, type of cement, water/cement ratio, temperature during curing etc influence the rate of strength gain of concrete

1

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

On the right is the slab formwork for a suspended concrete slab to a multi story building, but this system of concrete formwork could just as easily be used on an owner builder house What you see is a series of steel frames with cross braces holding them together They have adjustable screw jacks at the bottom and top The top jacks carry heavy timber bearers, (150 x 100) at say 10Our offering includes engineering services, slab installations, formwork, in situ slabs, Echo rib & block slabs, concrete rib & block slabs, coffer slabs, concrete staircases & ready mix concrete We have enough equipment & formwork to handle the construction of any concrete slabs in Pretoria from 5 m ² to 00 m² in one pour So if you need a competitive price on your next concrete slab39m Hbeam = 51 = 139 pieces;

Difference Between Formwork Shuttering Centering Staging Scaffolding

R Building Constructing Concrete Floor Slab Building Course Of Suspended Slab Formwork Metal Reinforcement Windown Installation Service

Suspended Slabs We install all sizes of suspended slabs, from stunning mezzanines and boutique homes to all types of commercial projects Besides expertise in suspended slabs, we can also deliver slab on ground, depending on project requirementsFlat Slab Formwork and Falsework" (Ref 3) The rationale of the research was to promote fast track construction, economise on equipment and minimise the labour content See Figure 3 This meant also that the slabs were conventional reinforced concrete with readymix concrete of a strength that was readily available at the time (ie a C30/37 mix) It was also realised that using

Flexible Forming System Designed To Reduce Time Cost Of Construction Building Design Construction

Floor Formwork Doka

Formwork Construction In Structures

Cornerstone Building Civil Engineering Suspended Slab With Removable Formwork Ready For Concrete Pouring Looking At The Example In The Image The Steel Bars Are There To Withstand And Counteract The

Safety Suspended Slab Formwork Shifting Trolley With Hydraulic Power

Suspended Floor Flying Table Forms Concrete Slab Shuttering Panel Formwork Buy Kitsen Flying Table Forkwork Forms Suspended Floor Slab Formwork Product On Alibaba Com

Suspended Slab Formwork Cottage Renovation Outdoor Structures Renovations

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Flying Table Formwork For Large Area Slab Concrete Construction

James Loder Construction Blog Site Visit Suspended Slabs And Suspended Ceilings

Architectural Aluminum Formwork System If Formwork System Kitsen Fastform

Lift Slab Construction Wikipedia

Structure Suspended Slab Home Building In Vancouver

N S Concrete Sydney Suspended Concrete Slab Specialists 40 Yrs Exp

System Category Slab Formwork Formwork Direct

Concrete Slab Floors Yourhome

Concrete Floor Slab Construction Process The Constructor

Back Propping Idh Design

Suspended Slab Formwork Cottage Renovation Cottage Renovations

What Are Formwork Shuttering Centering Staging And Scaffolding

Peri Gridflex Slab Formwork System Youtube

Safety Concrete Formwork For Suspended Slabs China Slab Formwork Aluminum Shutter Made In China Com

Q Tbn And9gct 1b6uyaco2szeh5phcdwah Prbgcjhxxxjkxu7brkxsn5krht Usqp Cau

Suspended Slab Construction Process Traditional Timber Formwork Steel Rebar Concrete Process Youtube

Expanded Polystyrene Eps Formwork Block Zlabform Zego Pty Ltd For Flooring Concrete Floor Slab Insulating

Daniel Son Project Services Ltd Groundworks London Underpinning Basement Conversions Cellar Conversions Drainage Repairs Foundations Excavations Groundwork Contractors Underpinning Contractors Structural Works Asuc Contractors Cilil Engineering

Design And Calculation Of Formwork Requirement Of Slabs Structville

Adjustable Prop Vertical Robust Suspended Slab Formwork System Adjustable Prop Manufacturer From China Cccc Fwk International Formwork Corporation

R Development Floor Beam And Suspended Slab Formwork Work Course Of Conventional Timber Formwork Shuttering Works Windown Installation Service

Cold Rolled Steel Slab Formwork Scaffolding Building System For Construction For Sale Slab Formwork System Manufacturer From China

File Slab Formwork Tables Jpg Wikimedia Commons

Suspended Slab Success Build It International

Design And Calculation Of Formwork Requirement Of Slabs Structville

China Kitsen Modular Slab Edge Formwork On Suspended Slabs China Slab Formwork Formwork Panel

Slab Formwork Ulma Construction

4 1 Formwork For Concrete Slab

Shuttering Contractors Concrete Formwork Contractors Am Formwork

How To De Shutter The Slab Of A High Rise Building

Formwork For Decks And Floors Concrete Construction Magazine

Formwork Contractors Melbourne Suspended Slabs 03 9132 8155

Simple Fast Work Slab Formwork Systems High Load Bearing Scaffolding S Ts

Suspended Slab Success Build It International

Cordek Com Uploads Brochures Cordek Construction Solutions Brochure Pdf

Formwork Bearers

Formwork Contractors Melbourne Suspended Slabs 03 9132 8155

Slab Formwork Mevaflex Meva Schalungs Systeme

Design And Calculation Of Formwork Requirement Of Slabs Structville

Www Istructe Org Sitefiles Handlers Downloadfile Ashx Productid 870

Large Area Formwork Top 50 By Acrownz Issuu

Concrete Slab Floors Yourhome

Aluflex Slab Formwork System Formwork Direct

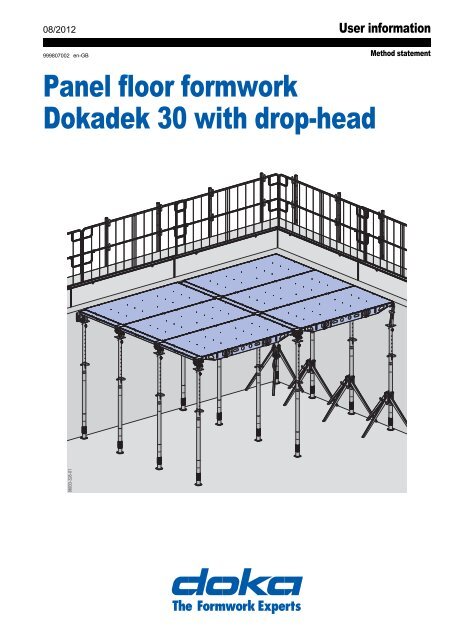

Panel Floor Formwork Dokadek 30 With Drop Head Doka Lietuva

Concrete Slab Wikiwand

Installation Wood Formwork For Concrete Slabs And Beams Of Roofing Construction Youtube

/concreting-formwork-for-the-foundation-857756224-5b7ed9cdc9e77c00573a1357.jpg)

Safety Installation And Removal Of Formwork

Slab Meva Formwork Systems

Slab Edge Formwork

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Formdeck Fd300 Durable Permanent Metal Tray Formwork Reinforcement System For Suspended Concrete Slab Construction

Q Tbn And9gcstfx Rzcjfxnpwdzm9ih1flj47wyelb0j8gzsjt9jw Xwpgsin Usqp Cau

Suspended Slab Formwork Cassaform Construction Systems

Safety And Health Lessons Learnt Formwork Incident Office Of The Federal Safety Commissioner

This Is Everything Inside A Suspended Slab That A Lot Of People Do Not See We Have A Concrete Beam To The Middle Left Han Storey Homes Ideal Home Construction

Xypex Xypex For Waterproofing Suspended Slab Concrete Xypex

Murform Concrete Formwork Contractor Uk Ireland Mitcham S Corner Cambridge Murform Concrete Formwork Contractor Uk Ireland

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Beam Formwork Concrete Slab System Peri Construction Beam Waler W Adjustable Angle Forkhead Jacks

Concrete Slab Wikiwand

Formwork For Decks And Floors Concrete Construction Magazine

5 Things To Look For When Inspecting A Suspended Concrete Slab

Concrete Formwork Slab Shoring System For Construction Buy Concrete Slab Formwork Scaffolding System Suspended Concrete Fomwork Safety Concrete Formwork For Suspended Slabs Product On Alibaba Com

Concrete Formwork For Slabs

Slab Formwork Dokadek 30 Doka

4 1 Formwork For Concrete Slab

Formwork To Suspended Slabs Beams And Columns Youtube

Safety And Health Lessons Learnt Formwork Incident Office Of The Federal Safety Commissioner

Suspended Slab Formwork Cassaform Construction Systems

Suspended Slab Formwork Cassaform Construction Systems

0 件のコメント:

コメントを投稿